The Dangers of a Failing Hydraulic Hose & How to Prevent It

Understanding the Risks in Industrial and Construction Settings

In high-demand environments like construction sites, manufacturing facilities, and heavy equipment operations, hydraulic hoses are critical components that keep machines moving. But when a hydraulic hose fails, the results can be sudden, dangerous, and expensive.

From costly equipment damage to serious safety hazards, a failed hydraulic hose isn’t just an inconvenience—it’s a risk your business can’t afford to take. In this post, we’ll break down the dangers of hydraulic hose failure and how to prevent problems before they start.

What Happens When a Hydraulic Hose Fails?

Hydraulic hoses are designed to handle high pressure and flow, often under extreme conditions. But when hoses age, get damaged, or are improperly maintained, they become a weak point in the system—and failure can happen without warning.

Common consequences of hose failure:

🔴 Sudden loss of hydraulic power

🔴 Equipment shutdowns and jobsite delays

🔴 High-pressure fluid leaks or spray

🔴 Injury to operators or nearby workers

🔴 Contaminated work areas

🔴 Costly emergency repairs or replacements

Top Dangers of Failing Hydraulic Hoses

1. Operator Injury & Safety Hazards

One of the most serious dangers of hose failure is the risk to worker safety. High-pressure hydraulic fluid can escape suddenly, posing multiple hazards:

- Injection injuries – Fine streams of pressurized fluid can puncture the skin, leading to serious internal injuries that may not be immediately visible.

- Slips and falls – Fluid leaking onto walking surfaces increases the risk of workplace accidents.

- Burns or fire – If fluid contacts hot components or electrical sources, it may ignite.

Injury from hydraulic hose failure is a real and documented risk—especially in industrial and construction settings where workers are in close proximity to equipment.

2. Equipment Damage & Downtime

When a hose bursts or leaks, it often causes:

- Loss of pressure in the hydraulic system

- Reduced performance or complete equipment shutdown

- Damage to pumps, motors, or cylinders due to improper fluid delivery

This kind of unplanned failure leads to costly repairs and significant project delays—especially if equipment must be removed and transported for service.

3. Environmental Contamination

Leaking hydraulic fluid can contaminate:

- Soil and water sources

- Concrete and jobsite surfaces

- Internal components of machinery

Hydraulic fluid spills can lead to fines, cleanup costs, and reputational damage, especially on regulated or environmentally sensitive worksites.

How to Prevent Hydraulic Hose Failure

The good news? Most hose failures are entirely preventable with proper maintenance and inspection. Here’s how to stay ahead of the problem:

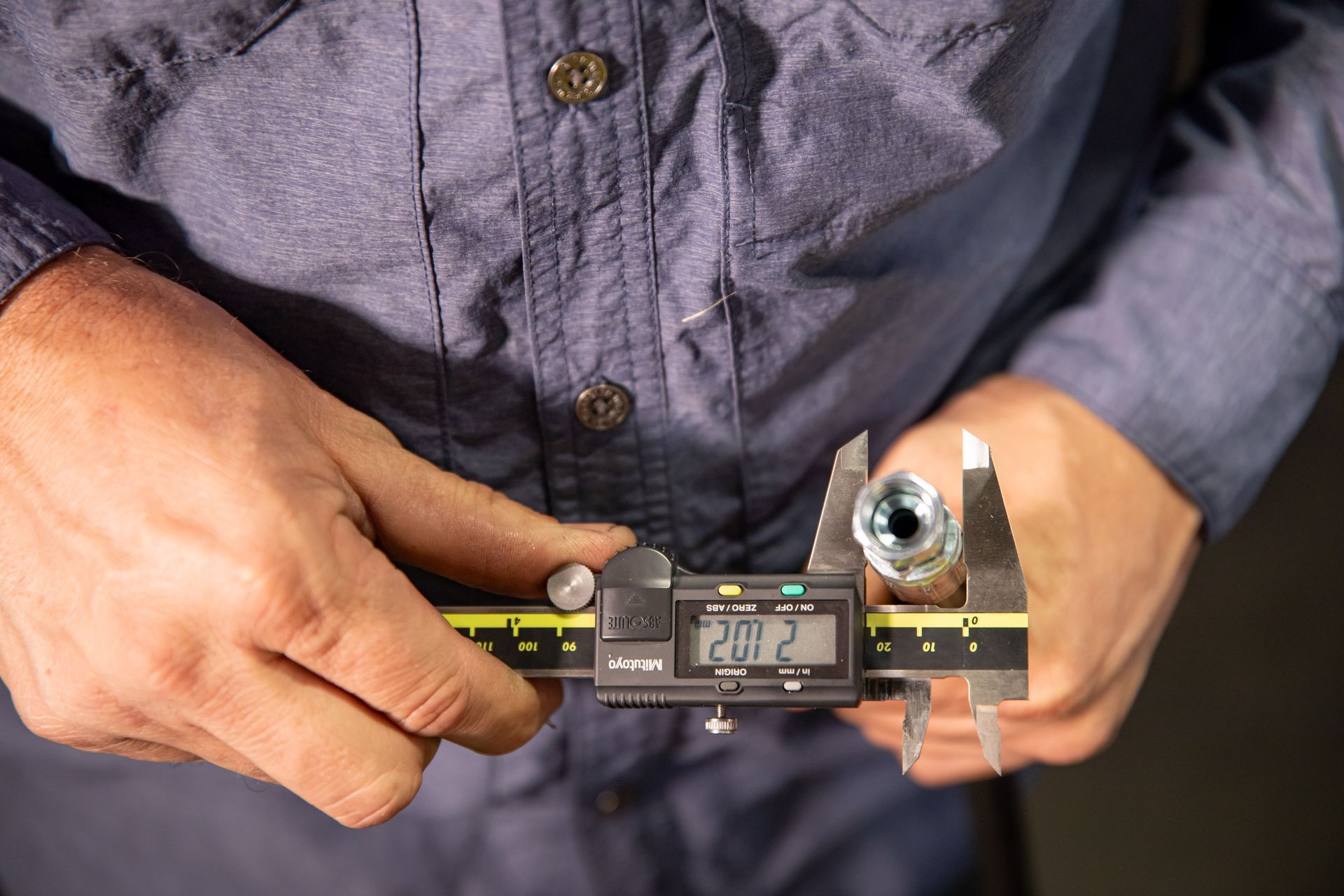

✅ 1. Regular Inspections

Check your hydraulic hoses frequently for signs of:

- Cracks, cuts, or abrasions

- Leaks or fluid seepage

- Bulges, kinks, or stiffness

- Worn-out fittings or connectors

Early detection means small issues can be fixed before they turn into major failures.

✅ 2. Replace Hoses Before They Fail

Hoses have a limited lifespan. If you’re relying on hoses that are:

- Over 5 years old

- Showing signs of wear

- Used in extreme environments

…it’s time to consider a proactive replacement before they break down under pressure.

✅ 3. Use the Right Hose for the Job

Not all hoses are created equal. Make sure your hoses are rated for:

- The correct pressure range

- The type of fluid used

- The temperature and environmental conditions

Using the wrong hose for your equipment or application increases the risk of failure dramatically.

✅ 4. Keep Hose Routing Clean & Clear

Avoid routing hoses near sharp edges, pinch points, or moving parts. Use clamps or protective sleeves when needed to prevent abrasion and extend hose life.

✅ 5. Schedule On-Site Maintenance & Repairs

Mobile hydraulic hose repair services like Van Otterloo Inc eliminate downtime by replacing hoses on-site and on-demand. With expert technicians, you can have hoses repaired or replaced the same day—keeping your crew moving and your equipment safe.

Protect Your Team, Your Equipment, and Your Bottom Line

Hydraulic hose failures aren’t just mechanical issues—they’re business risks. From injured employees to missed deadlines and unexpected repair costs, the impact of a failed hose can be severe.

With proactive inspection, proper hose selection, and access to on-site emergency repair, you can avoid costly breakdowns and maintain a safe, productive jobsite.

Need Emergency Hose Repair in San Diego?

At Van Otterloo Inc, we specialize in immediate, on-site hydraulic and industrial hose repair and replacement. Whether you're dealing with a leak, a burst, or aging hoses, we bring the shop to your site—minimizing downtime and maximizing safety.

Don’t wait until it fails— Call Van Otterloo Inc and keep your equipment running safely and efficiently.