How On-Site Hose Repair Saves Time & Money for Your Business

The Benefits of Immediate Mobile Service for Minimizing Downtime

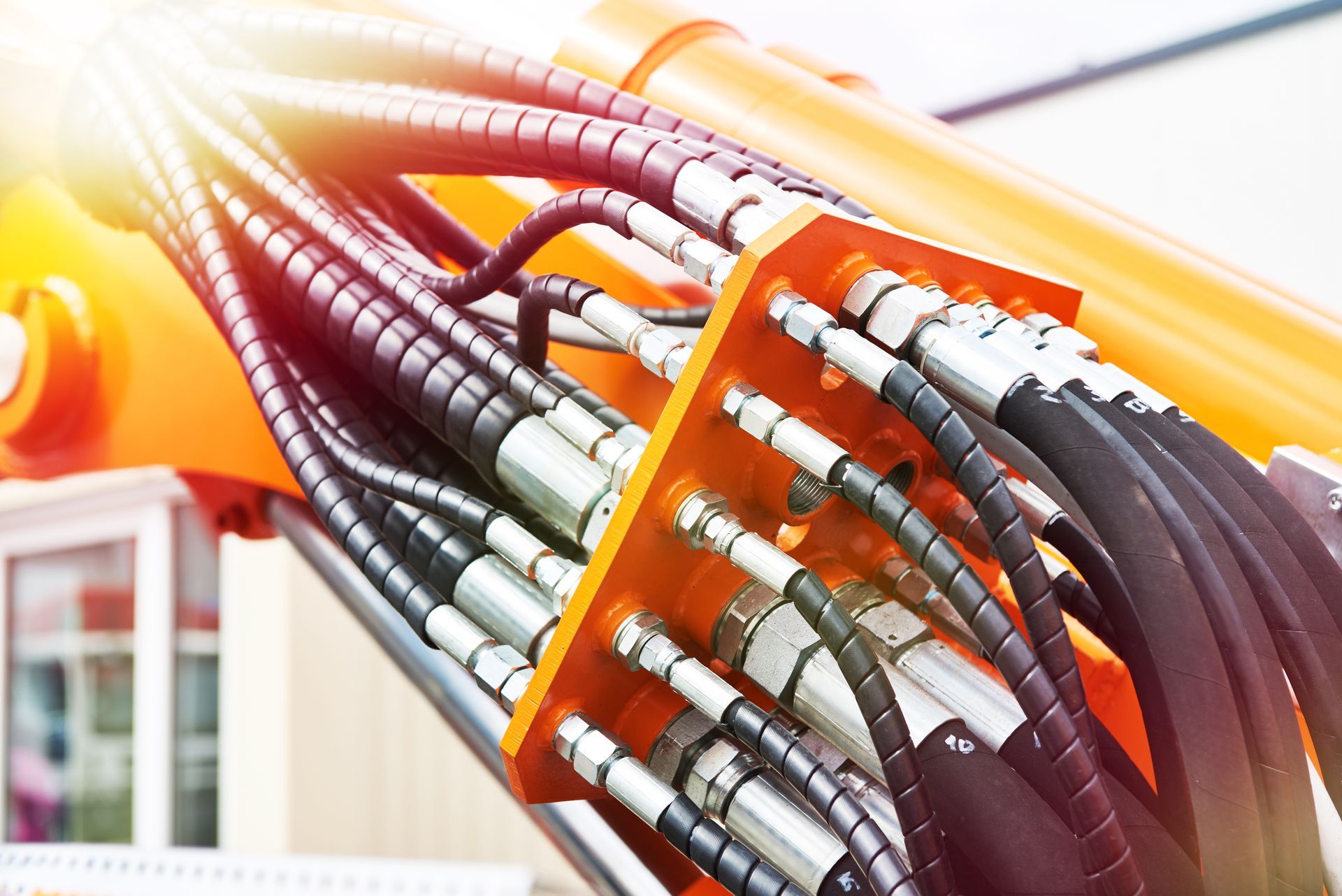

In industries that rely on hydraulic and industrial hoses—construction, manufacturing, agriculture, and heavy equipment operations—downtime isn’t just an inconvenience; it’s a significant financial drain. When a hydraulic hose fails, operations come to a standstill, delaying projects, increasing labor costs, and potentially damaging equipment.

Traditional hose repair often means removing the damaged hose, transporting it to a repair shop, waiting for a replacement, and reinstalling it—wasting valuable hours or even days. But

on-site hydraulic hose repair services eliminate this downtime, getting your equipment back up and running immediately.

1. Minimizes Downtime & Keeps Your Business Running

Every minute your machinery is down, you're losing money. Whether running construction equipment, agricultural machinery, or an industrial facility, waiting for a hose replacement can halt operations.

On-Site Repair Advantage:

✅ A technician arrives at your location with the necessary tools and materials

✅ The damaged hose is assessed, removed, and replaced on the spot

✅ Your equipment is back in operation within hours—not days

Instead of waiting for a shop to build and deliver a new hose, on-site repair immediately gets you back to work.

2. Eliminates Transportation & Labor Costs

Without on-site service, a damaged hose means extra labor and logistical headaches. Someone has to remove the faulty hose, transport it to a shop, wait for repairs, and reinstall it. This often requires additional crew members, rental equipment, or costly delays.

On-Site Repair Advantage:

✅ No need to transport machinery or hoses—technicians come to you

✅ Reduced labor costs since workers aren’t left idle waiting for repairs

✅ No extra expenses for rental equipment or backup machinery

By cutting out unnecessary transportation and labor costs, on-site service keeps your budget in check.

3. Prevents Costly Equipment Damage

A failing hydraulic hose doesn’t just stop operations—it can cause significant damage to your equipment. A burst hose can lead to:

🔴 Hydraulic fluid leaks that contaminate surrounding components

🔴 Increased wear on pumps, cylinders, and fittings

🔴 Overheating due to improper fluid flow

🔴 Potential safety hazards for operators and workers

On-Site Repair Advantage:

✅ Immediate replacement prevents further wear and tear on equipment

✅ Prevents hydraulic leaks that could damage other machine components

✅ Ensures proper pressure levels and performance for long-term reliability

Fixing a failing hose before it escalates saves thousands in equipment repair or replacement costs.

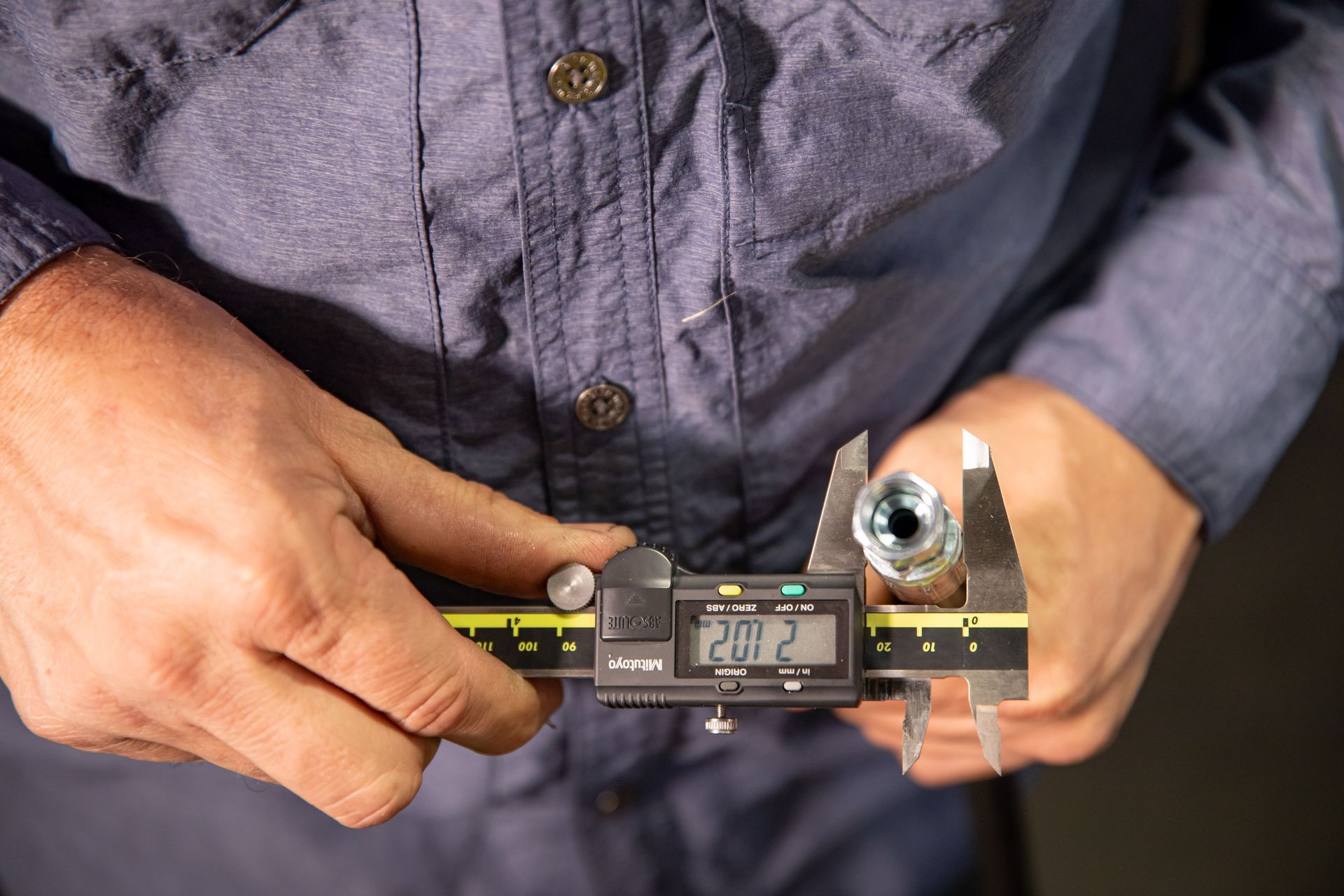

4. Custom-Fitted Solutions On Demand

Off-the-shelf hoses may not always fit your machinery correctly, leading to performance issues, premature wear, or compatibility problems.

On-Site Repair Advantage:

✅ Mobile technicians build

custom hydraulic hoses tailored to your specifications

✅ Proper fittings and materials ensure better durability and performance

✅ No need to modify or “make do” with an ill-fitting replacement hose

With a custom-fitted hose replacement done on-site, you get precision and reliability without compromise.

5. Reduces Unplanned Emergency Costs

Emergency breakdowns can lead to unexpected expenses, such as:

🔴 Rush-ordering parts at premium prices

🔴 Overtime labor costs to catch up on lost time

🔴 Losing contracts or missing deadlines due to project delays

On-Site Repair Advantage:

✅ Rapid response means no costly emergency shop repairs

✅ Scheduled maintenance services help prevent unexpected failures

✅ Avoids penalties from delayed projects or contract breaches

By solving hose failures on the spot, businesses avoid hefty emergency expenses and stay ahead of costly breakdowns.

6. Increases Workplace Safety & Reduces Liability

Hydraulic fluid leaks or unexpected hose failures pose serious safety risks to workers. High-pressure leaks can cause:

⚠️ Slips and falls from leaked fluid

⚠️ High-pressure fluid injection injuries

⚠️ Equipment malfunctions leading to accidents

On-Site Repair Advantage:

✅ Immediate leak repair reduces environmental and workplace hazards

✅ Prevents high-pressure failures that could injure employees

✅ Ensures compliance with safety standards and industry regulations

A safe worksite means

fewer injury-related costs and liabilities for your business.

Maximize Productivity with Immediate On-Site Hose Repair

Waiting for off-site repairs isn't an option for businesses that depend on hydraulic and industrial hoses. On-site repair services bring convenience, efficiency, and cost savings to your operations, ensuring:

✅

Less downtime and

faster turnaround

✅

Lower costs on labor, transportation, and emergency fixes

✅

Safer operations with reduced workplace hazards

✅

Custom hose solutions tailored to your equipment

If your business relies on hydraulic machinery, investing in on-site hose repair services is a game-changer for saving time and money.

Need Immediate Hydraulic Hose Repair in San Diego? We’ve Got You Covered!

At Van Otterloo Inc, we specialize in immediate, on-site hydraulic and industrial hose repair—so you don’t have to deal with costly delays and downtime. Our mobile service team arrives fully equipped to replace damaged hoses on the spot, getting your equipment back to work fast.

📞

Call Us Now:

(760) 703-1243

🌐

Visit Us:

456 E Mission Rd, Ste 120, San Marcos, CA 92069

Don’t let a damaged hose slow your business down.

Get back to work today with fast, reliable on-site service!

Explore

Company

Location

456 E Mission Rd, Ste 120

San Marcos, CA 92069

Open Monday - Friday 8am - 5pm

All Rights Reserved | Van Otterloo, Inc.

Privacy Policy | Web Design by GoBeRewarded, LLC